anyone have a rear trailing arm bushing tool?

#1

anyone have a rear trailing arm bushing tool?

like this one:

http://shoptoolsshoptools.com/shopexd.asp?id=2784

i need to replace mine. does anyone have one they can rent to me for a weekend?

please PM me if you've got one, or maybe even know of where i could rent one...

thanks!

peter

http://shoptoolsshoptools.com/shopexd.asp?id=2784

i need to replace mine. does anyone have one they can rent to me for a weekend?

please PM me if you've got one, or maybe even know of where i could rent one...

thanks!

peter

#4

mmmm... I don't think anywhere would rent them out.

You can try using a huge socket or cup or something that fits on the outer bushing. You'll have to hit it really hard and have something with a pry bar or something on the other end of the arm for support. That's a pretty ghetto way of doing it, if you dont want to cough up the big bucks

You can try using a huge socket or cup or something that fits on the outer bushing. You'll have to hit it really hard and have something with a pry bar or something on the other end of the arm for support. That's a pretty ghetto way of doing it, if you dont want to cough up the big bucks

#6

Removing rear trailing arm bushing

I just replaced a rear trailing arm bushing on my civic. To get the old one out I took a hacksaw, removed the blade, passed the blade through the bushing and then connected it back up to the saw upside down. Like this: (only still on the car obviously)

and cut right through the outer metal sleve of the bushing. I then hit it with a hammer until it started to move.

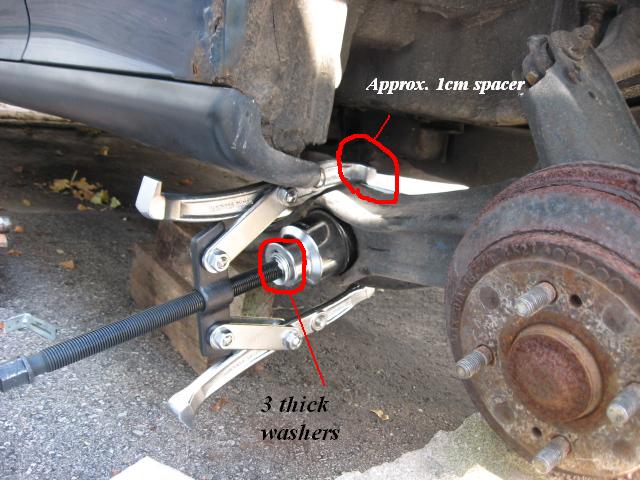

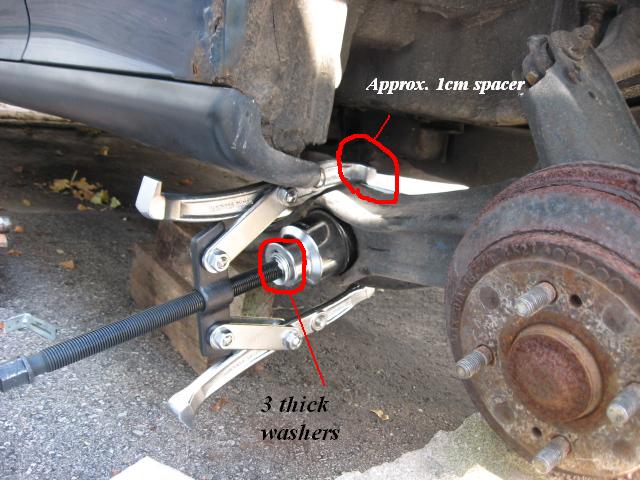

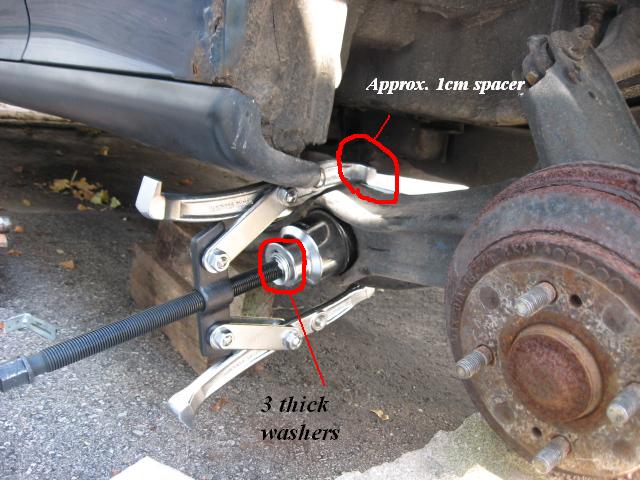

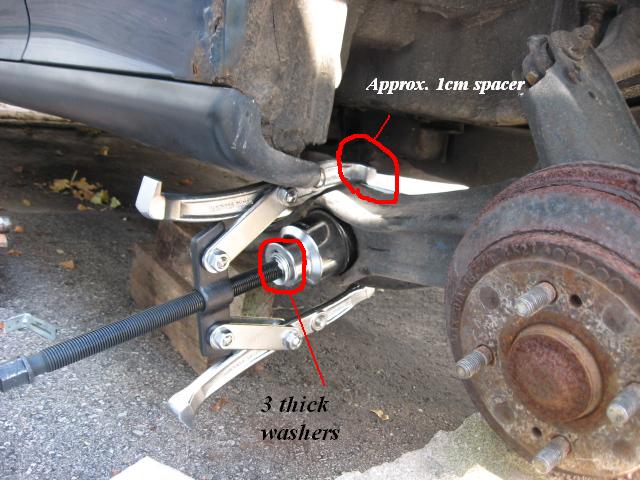

To get it out the rest of the way I used a large socket (1" drive, 2-3/16") and an 8" two jaw puller, both purchased from Princess Auto, to press it out

Like this:

As you can see from the pic I had to use some washers to bridge the 1 inch square hole in the socket. When I do this again, to the other side, I'll probably get some metal welded in there as the washers where a pain in the *** to deal with. It helps to actually tape the washers to the socket to keep them in place as you position the puller.

I also had to use something as a 1 cm spacer on the top 'leg' of the puller as the bottom of the trailing arm is thicker then the top. I just used 2 metal right angle brackets that I had lying around, but any flat piece of metal approx 1 cm thick should work.

Once the old bushing was out I cleaned up the hole in the trailing arm with some sand paper and applied a little grease to make the new bushing go in easier.

The new one pressed in no problem, the same way as pressing the old one out.

Before removing the old bushing dont forget to measure the distance it is pressed in and mark the angle it's at at ride height.

See this link: http://downloads.hondatech.info/Auto...n/x00-006e.pdf

Hope this helps,

Matt

and cut right through the outer metal sleve of the bushing. I then hit it with a hammer until it started to move.

To get it out the rest of the way I used a large socket (1" drive, 2-3/16") and an 8" two jaw puller, both purchased from Princess Auto, to press it out

Like this:

As you can see from the pic I had to use some washers to bridge the 1 inch square hole in the socket. When I do this again, to the other side, I'll probably get some metal welded in there as the washers where a pain in the *** to deal with. It helps to actually tape the washers to the socket to keep them in place as you position the puller.

I also had to use something as a 1 cm spacer on the top 'leg' of the puller as the bottom of the trailing arm is thicker then the top. I just used 2 metal right angle brackets that I had lying around, but any flat piece of metal approx 1 cm thick should work.

Once the old bushing was out I cleaned up the hole in the trailing arm with some sand paper and applied a little grease to make the new bushing go in easier.

The new one pressed in no problem, the same way as pressing the old one out.

Before removing the old bushing dont forget to measure the distance it is pressed in and mark the angle it's at at ride height.

See this link: http://downloads.hondatech.info/Auto...n/x00-006e.pdf

Hope this helps,

Matt

Last edited by Monsoon; 23-Nov-2008 at 06:57 PM.

#7

I just replaced a rear trailing arm bushing on my civic. To get the old one out I took a hacksaw, removed the blade, passed the blade through the bushing and then connected it back up to the saw upside down. Like this: (only still on the car obviously)

and cut right through the outer metal sleve of the bushing. I then hit it with a hammer until it started to move.

To get it out the rest of the way I used a large socket (1" drive, 2-3/16") and an 8" two jaw puller, both purchased from Princess Auto, to press it out

Like this:

As you can see from the pic I had to use some washers to bridge the 1 inch square hole in the socket. When I do this again, to the other side, I'll probably get some metal welded in there as the washers where a pain in the *** to deal with. It helps to actually tape the washers to the socket to keep them in place as you position the puller.

I also had to use something as a 1 cm spacer on the top 'leg' of the puller as the bottom of the trailing arm is thicker then the top. I just used 2 metal right angle brackets that I had lying around, but any flat piece of metal approx 1 cm thick should work.

Once the old bushing was out I cleaned up the hole in the trailing arm with some sand paper and applied a little grease to make the new bushing go in easier.

The new one pressed in no problem, the same way as pressing the old one out.

Before removing the old bushing dont forget to measure the distance it is pressed in and mark the angle it's at at ride height.

See this link: http://downloads.hondatech.info/Auto...n/x00-006e.pdf

Hope this helps,

Matt

and cut right through the outer metal sleve of the bushing. I then hit it with a hammer until it started to move.

To get it out the rest of the way I used a large socket (1" drive, 2-3/16") and an 8" two jaw puller, both purchased from Princess Auto, to press it out

Like this:

As you can see from the pic I had to use some washers to bridge the 1 inch square hole in the socket. When I do this again, to the other side, I'll probably get some metal welded in there as the washers where a pain in the *** to deal with. It helps to actually tape the washers to the socket to keep them in place as you position the puller.

I also had to use something as a 1 cm spacer on the top 'leg' of the puller as the bottom of the trailing arm is thicker then the top. I just used 2 metal right angle brackets that I had lying around, but any flat piece of metal approx 1 cm thick should work.

Once the old bushing was out I cleaned up the hole in the trailing arm with some sand paper and applied a little grease to make the new bushing go in easier.

The new one pressed in no problem, the same way as pressing the old one out.

Before removing the old bushing dont forget to measure the distance it is pressed in and mark the angle it's at at ride height.

See this link: http://downloads.hondatech.info/Auto...n/x00-006e.pdf

Hope this helps,

Matt

thanks for the reply - yeah, i have a steering wheel/gear puller like that, and i was thinking about giving that a go. i would just need the massive socket (i have everything else). great idea with the hack saw!

i might wait until spring or see if i can use a friend's garage... it's a bit too cold to work in the street now.

thanks!

peter

Thread

Thread Starter

Forum

Replies

Last Post

Monsoon

Honda Civic (+ other) Parts/Accessories for Sale or Trade

2

09-Jun-2012 03:37 PM

DTS

Honda Civic (+ other) Parts/Accessories for Sale or Trade

0

28-Feb-2011 05:02 PM

R1020

Honda Civic (+ other) Parts/Accessories for Sale or Trade

0

21-Sep-2009 02:14 PM

R1020

Honda Civic (+ other) Parts/Accessories for Sale or Trade

0

09-Sep-2009 11:34 AM

R0Y

Honda Civic (+ other) Parts/Accessories for Sale or Trade

1

25-Sep-2004 07:37 PM